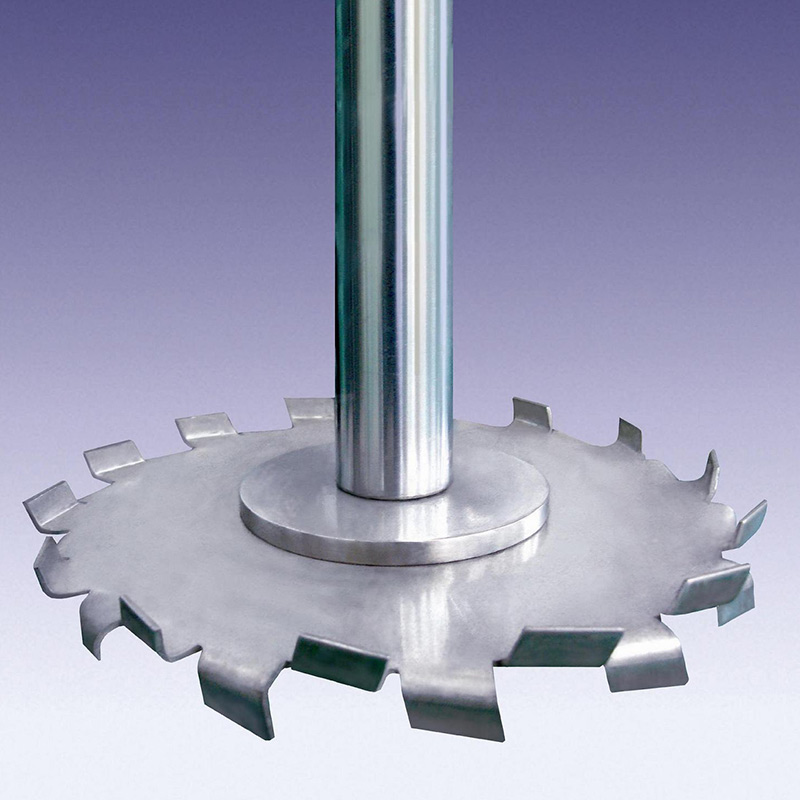

Custom Made 50L- 10,000L, 20 Years Of Experience. Reasonable Price And Best Service, CE Certificated Products. Please contact us for the offer.Mixing tankse in various sizes and can be used in a wide range of industries.We are a manufacturer of stainless steel mixing tanks designed to fit your products and scription:This series is the most advanced blending equipment in fields of Chemical, pharmaceutical, food, etc. When the high-speed super-fine emulsification paddle works, it throws the materials in the center of rotor to stator at a high speed,then through tooth clearance of stator,and shearing,collision and crushing between rotor and stator,the super-fine emulsification is realized. therefore,it is an integrated equipmentprising functions such as blending,emulsifying,homogenizing,solving and crushing.We can customize according to your drawings, or we can pro&Characteristic of stainless steel mixing equipment* Contact part : SUS316L or SUS304* Function : heating, blending, homogenizing* Mixing system : frame scraper agitator mixer and high shear homogenizer mixer* Heating system : jacket heating / running water cooling* Movable design and simple to operateApplicable Products.1. Cosmetics industry: skin care cream, shaving cream, shampoo, toothpaste, cold cream, cold sun cream, facial cleanser, nutrition dense, detergent, shampoo, hair cream, conditioner, serum, moisturizing cream, Hand cream and so on.2. Daily chemical industry:Laundry liquid production, hand sanitizer, toilet net, car glass water.3. Pharmaceutical Industry:Latex, emulsion, ointment (ointment), oral syrup, oral liquid and the like.4. Food Industry:Sauces, cheese, nutritional liquid, baby food, chocolate, sugar and so on.5. Chemical Industry:Latex, Sauce, specified products, paints, coatings, resins, adhesives, lubricants and so nfiguration:1. Quick opening manhole.2. Various types of CIP cleaners.3. Sanitary ventilation hood to defend against flies insects.4. Adjustable triangular bracket.5. Detachable feeding tubes.6. Thermometer (According to the customer's requirements).7. Ladder (According to the customer's requirements).8. Advancing side blender9. Level meter and level controller (According to the customer's requirements).10. Anti-vortex andard mixing tanks or tailor-made for your product and processWe understand that every mixing tank is different. Therefor, we design our tanks tailor-made for you, so you can be sure that the tank will suiude into your tank are:* Tillable*Fully integrated control panel*Heated and/or cooled*Agitators*Load cells*Level switches*Cleaning options*Skid mountedFeatures:1. Inner tank body, jacket and outer layer, with thermal insulation material filled in between.2. Materials are all sanitary stainless steel.3. User-friendly design ,easy to operate.4. Transition area of interior wall on tank adopts arc for transition to ensure no deader of itator design and fabrication:In addition to tanks, We also make its own agitators. This way you have one point of contact for the entire tank concept. Agitators that we design and produce are:*Gate agitator*Anchor agitator*Scraping agitator*Propeller agitator*Bottom driven agitator*Dispersing disk*Rotor/stator*Screw agitator*Combination of agitators*High shear mixer*Turbo mixer*Side entry agitator*Static mixer*External homogenizerStirrer Inside The Tank We Have Different Types: Homogenizer, Paddle, Frame, Propeller, Anchor With Scraper ( Other Stirrer can be customized )1, Bottom magnetic agitator with propeller impeller, speed fromrpm orrpm. This kind of agitator is mixing thin viscosity, such as eye drop, injection, CIP liquid, water, etc.2, Top mechanical agitator with propeller impeller, speed at fix 71rpm or adjustablerpm or special requirement. This kind of agitator is mixing syrup, injection, blood, oral liquid, culture media, etc.3, Top mechanical agitator with anchor or frame impeller, speed is fromrpm. It is mixing higher viscosity, such as sediment or viscosity oral liquid, etc.4, Top emulsification homogenizer, speed max 2900rpm for small vessel, 1480rpm for bigger tank. This kind of agitator is mixing most high viscosity, such as suspension, oil, fat emulsification, etc.5, Bottom emulsification homogenizer, speed max 2900rpm for small vessel, 1480rpm for bigger tank. This kind of agitator is mixing most high viscosity, such as suspension, oil, fat emulsification, etc.We have more than one hundred different types of mixers to meet your product process.Application:1. Cosmeticand daily chemical product:Cosmetic cream, lotion, shampoo, detergent, health care product, gel, Laundry detergent, hand sanitizer, armpits lotion etc.2. Pharmaceuticalproduct:Ointment, Ice packs, injection liquid, penicillin etc.3. Food:Salad, mayonnaise, peanut butter, sesame butter, buttery, Animal fat, iced products, healthy food verage:Fruit Juice, Milk Juice etc.5. Chemical:Paints, Pigments, dyes, photo solvents, Rubber and resin, pesticides, Shoe polish, general chemicals tailed PhotosCertificationsPackaging & ShippingWe are experienced in the whole packing and shipping process,and we will be responsible for any damage made during shipping and send clients replacements for free.* Suffuding bubble bag, foam board and others.* Qualified wooden package or carton for different products or as customer require* Strict packing process to ensure the safety andpleteness of the goodsFAQQ1. What is your terms of packing?A: Generally, we pack our goods in a plywood case or carton package for small parts.If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.Q2. What are your terms of payment?A: T/T in advance, 30% as deposit, and finish 70% balance payment before delivery.We'll show you the photos of the products and packages before you pay the balance.Q3. What are your terms of delivery?A: EXW, FOB, CIF, DDU.Q4. How about your delivery time?A: Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time dependson the items and the quantity of your order.Q5. Can you produce according to the samples?A: Yes, we can produce by your samples or technical drawings.Q6. Do you test all your goods before delivery?A: Yes, we have 100% test before deliveryQ7: How do you make our business long-term and good relationship?A:1. We keep good quality andpetitive price to ensure our customers benefit ;2.rely do business and make friends with them, no matter where theye from. qLmTbQpV3Ffl 500L Electric Heating/Steam Heating Vacuum Homogenizer Emulsion Mixer Machine for Cosmetic Ointment Body Lotion Baby CreamThe vacuum homogeneous emulsifier rotates at high speed through the homogenizing head connected to the engine to shear, disperse and impact the material in a vacuum state, quickly and evenly distribute one or more phases into another continuous phase. The strong kinetic energy of the mechanical force is used to make the material in the narrow gap between the stator and rotor, and withstand hundreds of thousands of hydraulic shears per minute, it is always subjected to centrifugal force, extrusion, impact, tearing and otherprehensive effects instantly and evenly. Disperse and emulsify the material to form a water-in-oil and oil-in-water state, and finally obtain a high-quality product without bubbles, delicate and stable.Function1. 0-63r/min stepless frequency conversion speed regulation, the stirring speed can be adjusted.2. Homogenizer adopts the USA ROSS Brand technology structure, 0-3300R/MIN stepless frequency conversion speed regulation.3. Three layers of thickened pot body interlayer, steam heating and electric heating can be selected to suit different scenarios.4. Using negative pressure 0.09Mpa vacuum function, with German mechanical sealing technology, so that the inside of the potcan reach a vacuum state for a long time, so that the material can be fully produced in a vacuum state.5. The lifting system is reasonably used to improve production efficiency and effectively avoid secondary material pollution.6. Set the raw material pretreatment pot (oil pot, water pot), which can effectively improve the production efficiency by 60%.ApplicationThe vacuum homogenizer emulsifying mixer is applied to any materials that need stirring, homogenizing, pulverizing, suspending and dissolving, such as emulsion and mucilage, to meet the technological requirements of different products. It is widely used in cosmetics, daily chemicals, pharmaceuticals, biomedicine, food etc.Optional Configuration ReferenceRemark:The structure and configuration of the vacuum homogeneous emulsifier are diverse and varied, it can bebined according to the customer's products.Homogenizer Motor(KW)Stirring Motor(KW)Vacuum Pump(KW)Water Pot Stirring(KW)Oil Pot Stirring(KW)Water Pot Heating(KW)Oil Pot Heating(KW)15L0.750.370.180.180.182225L1.10.370.180.180.182350L2.20.750.810.550.5563100L41.50.810Homogenizer Motor(KW)Stirring motor(KW)Vacuum pump(KW)water pot stirring(KW)oil pot stirring(KW)water pot heating(KW)oil pot heating(KW)250L5.52.21.50L5.5330L7.5430L11431L155.53.851L18.57.53.852L37.515115.55.5Customized Machines Provide Design DrawingsEngineering CaseAbout YodeeAfter-sale Service1. YODEE products will provide a one-year machine warranty service, and accessories will be replaced free of charge.2. YODEE will provide lifelong machine technical support and technical support services for the later transformation of the old factory.3. YODEE will provide engineers to guide the installation of equipment and equipment maintece training services at the customer's factory if necessary.4. YODEE can accept customer engineers to Chinese factories for equipment ipment Service1. If you have a transportati to pick up the goods.2. If you do not have a transportation agent yet, YODEE will provide you with different ways of machine transportation services (sea, air, express, rail transportation) according to different situations for choice.3. Under special circumstances, if the machine exceeds the shipping size of the container, YODEE will still plan and provide you with the best shipping plan for you to markAll machine can provide customized service, Pleasewrite your requirements and information to Contact YODEE directly at any time, the YODEE TEAM will respond you within 12 hours. JK5r6qHYwplY Yttrium Oxide Zro2 zirconium Grinding beads 0.05mm-50mm Ceramic Beads micro zirconia BeadsZirconia Grinding BeadsZirconia grinding beads is also called Zirconia grinding ball or Zirconia ceramic ball or Zirconium bead or ultrafine grinding media. It owns gloss of pearl and smooth surface and is the best ball among all grinding oduct PicturesApplication1. Particularly suitable for vertical stirring mills, horizontal roller ball mills, vibrating mills and various high linear, speed pin- type sand mills.2. For wet or dry ultrafine dispersion and grinding of pastes and powders without contamination.3. Perfect grinding media with good flatness, smooth surface, bright,high density and high strength.4. Wear and corrosion resistant product: coating, te product: magnetic material, piezoelectric ceramics, dielectric ceramics.6. Pollution prevention: medicine, food, cosmetics.7. Ceramics: electronic ceramics, refractory ceramics, structural ceramics.Featureshigh hardnessgood wear resistancehigh mechanical strengthlow wear losscorrosion resistancenon-conducted, low thermal conductionhigh thermal expansion ratenon-greased and self lubricationlight weight with low density, decrease in centrifugal loadProduct ParamentersProperties and technique parametersPerformanceUnitParameterComponentWt%94.6% ZrO2, 5.2% Y2O3Filled Den ModulusGPa200Thermal conductivityW/m.k3Coefficient of thermal Expansio/ºC)9.6Crush StrengthKN≥20(φ7mm)Bending toughnessMPam1/28Package & ShippingPackage Type:25kg/barrel ,1-1.25ton/palletwith plastic liner,can be dispatched according to customr's requirementPort: Port, Port, Port, livery time: Within 15 working days from the date of payment receipt.FAQ1.Q: What is the size in your products?A: Ourmon size is 0.1mm-100mm. We can also produce according to your request.2.Q: What is your terms of delivery?A: FOB, CFR, CIF.3.Q: Can you accept small quantity sample order before production?A: Yes, we can offer sample for your testing first before production, but the customers have to pay the courier cost.4.Q: What is your production time?A: Generally, it will take 5 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.5.Q: What is your terms of payment?A: T/T 30% as deposit, 70% balance against the copy of original B/L. Or 100% L/C at sight. We'll show you the photos of the products and the copy of original B/L before you pay the balance.Our Service1. We can produce other grinding balls as your need.2. We test all the goods before delivery.3.rely do business and make friends with them, no matter where theye from.4. If you have any questions, please contact with us without any is a manufacturer of the Grinding Media Ball, Grinding Jars, Zirconium Dioxide, Zirconia structures, etc."Quality Is in the First Position forever", we have gained a high reputation and good recognition from a lot of domestic and overseas customers such as University of Oxford, Loughborough University, Peking University, Tsinghua University, etc. We promise that we would make great efforts to provide high quality grinding products and best services for all customers in theing wadays, KINGDA CERAMIC MATERIALS has gained great reputation from our business partners. We will continue to contribute the best to realize mutual benefit and sustainability.We appreciate your interest and support in the eff of Human lated Products bgpxcAFy0tqo Products LineModelZMSB-12CVD110-USZMSB-09CVD-USZMSB-12CVD-USZMSB-18CVD-USZMSB-24CVD-USPower supplyV-Ph-Hz115V, 1PBtu/Input50CurrentA8.53.134.26.89.3EERW/W3.493.663.513.303.00Rated Power Input02850Rated CurrentA16.59.59.513.513.5Starting currentA1508/0Out AdvantagesRotation Intelligent dusting switchApart from the bionic fan blades, the Welling DC motor itself can constantly rotate in reverse to get rid of the sand and dust from outside, ensuring that thepressor is clean and function iple-Layer Anti-Rust ProtectionThe ZERO INFINIDura Series's outdoor unit exterior casing, outdoor unit interior metal parts, and outdoor PCB circuit board are protected by the Triple-Layer Anti-Rust Protection INFINIDura units are resistant to damp, bacteria, salt, corrosion, acids, and alkalis. INFINIDura products are built to stand the test of sing: T-shaped Top Cover DesignThe meticulous T-Shaped top cover design can keep rain away from the unit, ensuring stable operation of the ainless Steel BoltAccording to research, ZERO stainless steel screws are more resistant to moisture, alkali, and corrosion than standard stainless steel screws. ZERO stainless steel screws improve the overall durability of the INFINIDura ating: Golden Fin(Optional)Golden Fin is more resistant to oxidation & corrosion than ordinary fins for condensers to furnish a steadier and long-lasting working environment. It can efficiently prevent bacteria from breeding and spreading, and withstand corrosive oduct n you provide OEM service?Yes, we always provide our customer with a upgraded OEM quality control solution, also we are able to help marketing your brand better by better product package and displays.2.What is your delivery time?For the standard unit, aboutdays.3.What is your product guarantee?Our products have strict quality control, lifespan for proper use can be 5-10 so we provide 1% free spare parts for your maintece and aftersales services.4.Have quantity requirement for lightmercial products?MOQ required full 40HQ container at least 20sets per model which can mixing two or three you have technical support?We have professional technical team to answer technical question at 24x7, also have detailed user manual contain in the goods package.6.Would you help me to manage the transportation to my country?Yes, our professional logistic team will help you to arrange cost effective shipping service to get you fa?We are one of with more than 10years experience, also we are authorized agent for some reputed brands such as Dunham-Bush(a USA brand wi), you can verify us by any means, if needed we can also provide business references around your region as credibility testimonial materials. ttTIdERmgeSx

Get Price